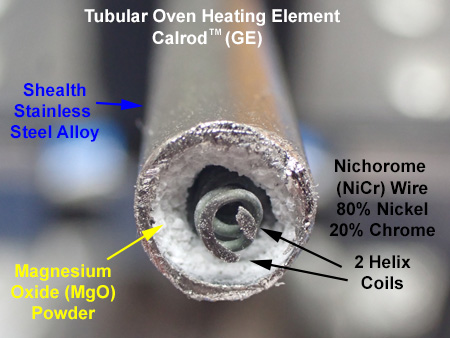

The heat source inside a tubular heating element is nichrome wire (80% Nickel and 20% Chrome). This wire has a relatively high resistance, and when electrical current is passed through it, it produces heat. To protect the nichrome heater wire, it is placed inside a metal tube or sheath. To keep the heater wire centered and from touching (shorting to) the metal tube, Magnesium Oxide (MgO) powder is packed between the heater wire and the metal tube. Magnesium Oxide is a very good conductor of heat and an excellent insulator of electricity. To produce more heat per inch (heat density), the heater wire is often shaped in the form of a spring (helix coil).

Tubular heating elements were invented by GE in 1915, and they first appeared in ranges in 1928. GE trade marked the name Calrods™ for their tubular heating elements.

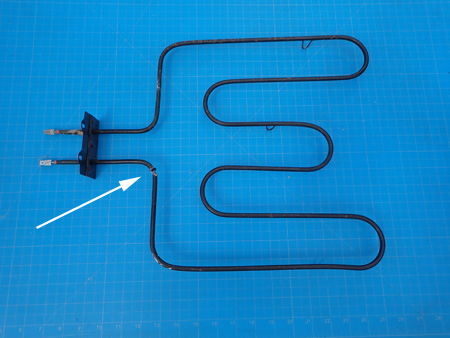

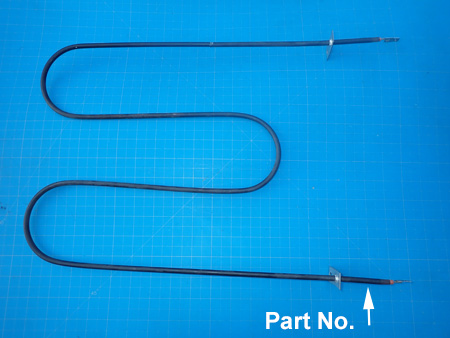

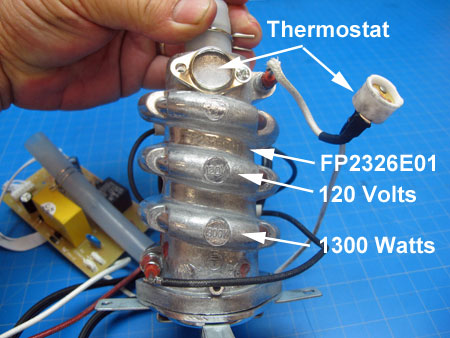

Tubular heating elements are used in ovens, cooktops, coffemakers, furnaces, water heaters and other appliances.